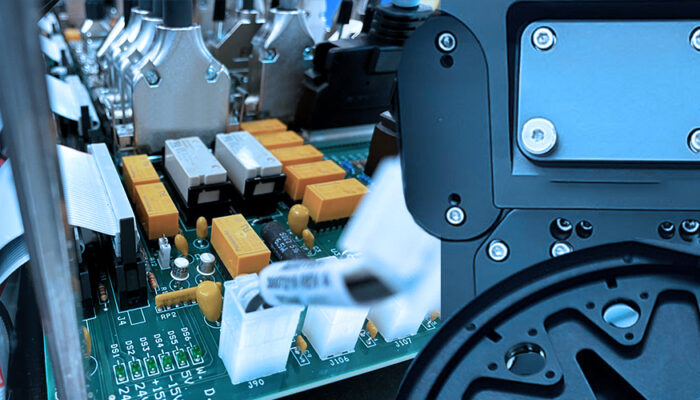

At Glide Write, we specialize in turnkey contract manufacturing solutions for high-precision systems across the semiconductor equipment, optical, and medical industries. With decades of combined expertise, our team delivers full-cycle production support — from prototype builds to final assembly and verification — all with the precision and reliability our clients depend on. Semiconductor Equipment Systems…

Precision Assembly

Glide Write has extensive experience in precision mass assembly work where placement of ceramic based micro devices must be bonded by cyanoacrylate adhesives and controlled within a tight tolerance of less than 2.54 microns in both X and Y direction.

Ultrasonic Cleaning Services

Precision, Purity, and Performance You Can Trust Our ultrasonic cleaning process delivers exceptional results for mechanical and precision components, combining advanced technology with cleanroom-level control. Using deionized (DI) water and qualified surfactants, each part undergoes a meticulously engineered cleaning cycle inside our Class 100 cleanroom to ensure absolute particulate control and surface purity. Through multi-stage…

Facility Clean Room

Glide Write is equipped with Class 100 raised floor clean room and full Deionized Water System to support its operations.